A new range of salmon leathers... what are we referring to?

- Virginie Ducatillon

- Aug 28, 2024

- 6 min read

To start the New Year on a high note, we wanted to surprise you with a new material that is still too little known: fish leather.

For this first sale, in addition to a superb range of classic leathers from a luxury house's dead stock (calfskin, cowhide, bullhide in a variety of finishes and colours), we'll be offering salmon leather from the dead stock of the Ictyos tannery!

Why this offer?

Our aim is to constantly innovate and introduce you to new materials.

We've chosen salmon leather because it's made from fish that we eat. What's more, salmon is one of the largest and most widely consumed fish. It's the most abundant and well-known resource. Its pattern is clearly recognisable and resembles exotic leather. It brings an extra touch of fantasy (in small touches, due to its size of course) to more classic leathers!

Why Ictyos?

At Adapta, human relationships and relationships shape what we do.

Adapta x Ictyos is first and foremost a wonderful human encounter, which began at the very beginning of our history, when we met tanners and leatherworkers at trade fairs. Today it's a closer encounter, as we are both winners of the ADC Au-delà du cuir incubator.

Ictyos is the work of three co-founders, Benjamin Malatrait, Gauthier Lefébure and Emmanuel Fourault, who met on the benches of chemistry and engineering schools. They knew nothing about the world of tanning and leather. By a happy coincidence, they realised there was a need (how to recycle the fish skins they were eating, in the same way that cattle skins are recycled for tanning) and wanted to come up with an innovative and responsible solution to the problem.

So it was a natural step for us to work with them on their dead stock, and to offer them a solution for reusing skins that have already been tanned, but which are not sold and are likely to end up in the bin in the long term!

In harmony with our manifesto on using existing materials / eco-responsibility / desirability / quality

Reusing materials that have already been produced:

We're sticking to our approach of making the most of materials that have already been produced, by offering materials from the unused stocks of luxury brands.

With Icytos and their salmon leather, this is no different: we only offer fish leathers from their dead stock... which represents half of their production!

As with all the dead stock to which we have access, we travel to check the quality and make an inventory of what we will be putting on sale on the day of the sales. On these salmon leathers, there could have been stains, flaws in the design of the scales, cuts during preparation by restorers, etc.). We put them aside to keep only the most beautiful skins.

So a qualitative pre-selection is made, according to our Adapta criteria.

An environmentally responsible approach:

Fish skins are a waste product from the food industry. So there is no increase in fishing.

Ictyos prefers vegetable tannins made from leaves, roots or fruit rather than bark, to minimise the impact on deforestation. The tannins used are chestnut and gallnut, for example. These are the most UV-resistant. Ictyos does not use any solvents or metallic products in the tanning process.

The fish skins are fully traceable: the tannery relies on a network of local partners and, thanks to this short circuit, reduces its carbon footprint.

Finally, salmon is not an endangered species like some exotic leathers, so there is no Cites.

Desirable materials:

Several finishes are possible on these salmon leathers.

The raw finish with raised scales and a natural, velvety feel, which is also more luxurious, and the more refined, shiny and sometimes metallic plated finish. All the ingredients needed to liven up a range of materials.

This type of backing is generally used for small objects, such as watch straps and card holders.

The only constraint is the size of the skins, but they can be used as inserts or details in a larger product: on shoes, leather goods, ready-to-wear clothing or decorative items. There are techniques for assembling them to form larger panels, such as patchwork.

Quality materials :

Salmon leather is a particularly hard-wearing leather, one of the strongest and finest. The multi-directional organisation of the marine fibres gives this leather a very high natural resistance.

The tanning process used for Ictyos marine leathers enhances its strength thanks to 2,0002 parameters set following 3 years of R&D and more than 2,500 tanning optimisations.

These marine leathers meet the many technical requirements of watch manufacturers. Numerous quality tests (light, humidity, dyeing), carried out by French and Swiss watch strap manufacturers, guarantee their resistance.

Finally, they select the finest fish skins from French agri-food partners.

Ictyos is a French tannery near Lyon that complies with REACH regulations.

Ictyos' visit last December... Follow the guide!

To find out everything there is to know about the Icyos tannery, we visited them last December near Lyon.

The purpose of the visit was both to conduct our usual inventory and quality check before any sale, and above all to gain a better understanding of their processes and what lies behind these magnificent fish leathers!

Interview with Gauthier Lefébure, one of the three co-founders of Ictyos

Valentin Sauer welcomed us for a tour of the tannery. He showed us the different stages involved in tanning these leathers.

We were also able to talk to Gauthier Lefébure, one of the co-founders who was there that day. And just as well: he's the production specialist!

We asked them lots of questions about the history of Ictyos, their approach, their beginnings, why vegetable tanning, and their business.

The fish leather tanning process

The tanning stages may differ slightly in certain respects for fish leather.

The tanning process involves between 30 and 40 individual steps.

The machinery is more similar to a tannery than a tannery (small fulling machines for small hides).

There's another special feature to bear in mind: salmon skin has no grain, just dermis. However, the leather is very resistant compared with cowhide of the same thickness, because its fibres are stratified (thickness of around 0.4-0.8mm).

Here's a breakdown of the steps involved in the tanning process, with photos!

Stage 1: The raw hide does not arrive salted, as is the case with traditional leather supports, with hair.

Stage 2: Skinning

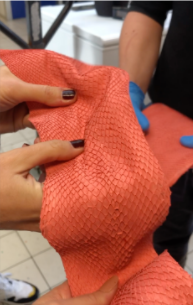

The skin arrives raw, so it has to be de-fleshed, i.e. what's left of the flesh has to be removed from the skin.

Stage 3: River work

The skin remains in the drum for 3 days

remove as much grease as possible,

liming, i.e. making it swell by adding alkaline substances. All the fats and impurities will come out of the hide.

Stage 4: Tanning

The hides macerate with the tannin for 3 days.

Stage 5: Drying the hides

The hides are taken out and spread out to dry for a few days.

Stage 6: Retanning

At this stage, the leathers are put back into the fulling drums.

Dry hides are taken back and put back into the fuller for a day to be dyed. Here, Ictyos adds colour and food to soften the leather.

Step 7: Drying on an easel

Stage 8: Framing

The hides are spread out and pulled with the pliers, to obtain the largest usable surface possible. The skin is brushed to remove the last visible scales.

Stage 9: Palising

Raw-finish leathers are softened using a machine with small pins to soften the hide. This stage can be carried out several times to ensure that the leather is as supple as possible.

Stage 10: Finishing in several stages

Finishing is carried out in several stages:

the spray booth adds colour to the leather (prefond as a primer, then a base coat of colour)

then a fixative is added to protect the colour

and finally a water-repellent is applied.

Step 11: The press

The leather is placed under a hot plate, with a lot of pressure, so that all the layers they've put on before start to ‘melt’ to really get an even layer. This is how you get smooth leather.

Stage 12: Final stage

Each hide from the same batch is stamped, to have several batches with different tracking numbers, and to be able to recreate a batch more easily if a customer requests it. demande.

So, we hope that fish leather and its tanning process now hold (almost) no secrets for you!

Now go online to our e-shop to discover our selection of salmon leathers, as part of our first exclusive sale of the year :)

Don't miss out!

Comments